KONČAR - Metal Structures

Precision shaped by experience. Modern welded components for energy, mobility and industry.

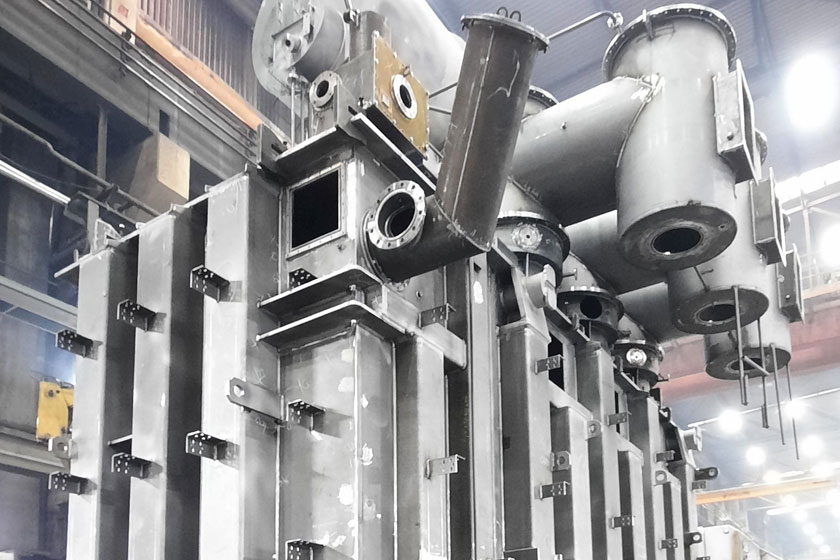

Experts for large-scale solutions - from the first spark to the finished product

We harness our machinery and expertise to manufacture large-scale, customer-specific welded components. Such impressive solutions pose a challenge even for the largest companies in the industry, but we excel at advanced projects where we can best showcase our capabilities.

We deliver generator components, rail vehicle components and isolated phase busbars. Our dominant technology is welding and metalwork, and our manufacturing capacity is defined by cranes with a lifting capacity of up to 2x63 tons and a maximum lifting height of 11 meters.

Corrosion protection

Learn more about the whole process.

Flagship projects

News & stories

Find out more about the recent activities, successes and flagship projects.

We’re always excited to meet new talent

Explore all jobs and open positions, find the right fit for you or send us an open application.

Quality and certifications

For many years, we have guided our business processes with an integrated quality management system, a fundamental component of our Corporate Management Policy.

Company: KONČAR – Metal Structures Ltd. for production

Abbreviated name: KONČAR – Metal Structures Ltd.

HQ and address: Fallerovo šetalište 22, 10 000 Zagreb

Management board: +385 1 3666 560

Technical office: +385 1 3655 869

Sales: +385 99 321 2282

Fax: +385 1 3667 515

E-mail: kmk.kmk@koncar.hr

VAT number: 05214448972

Company registration number MBS: 1114328