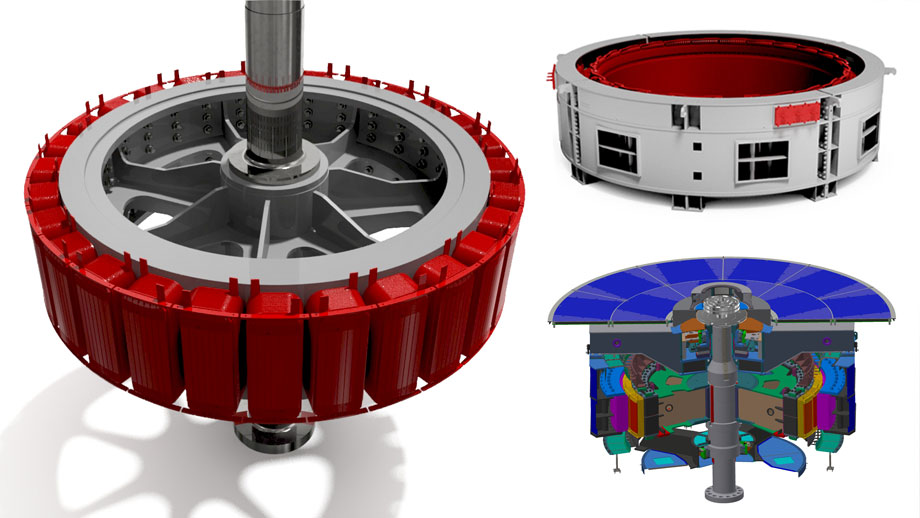

Our turnkey hydro generators are designed and manufactured to meet customer-specific needs:

- For Kaplan and Francis turbines: up to 250 MVA

- For Pelton turbines: up to 120 MVA

- Bulb type generators: up to 45 MVA

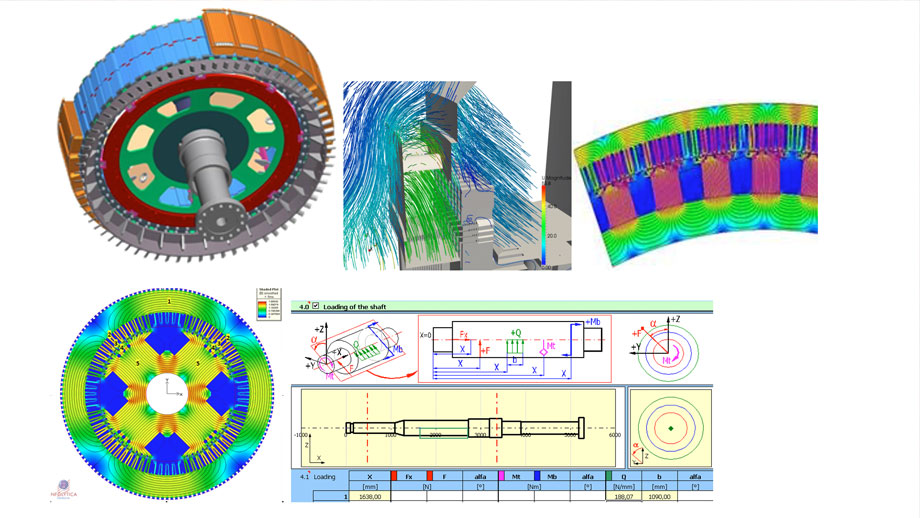

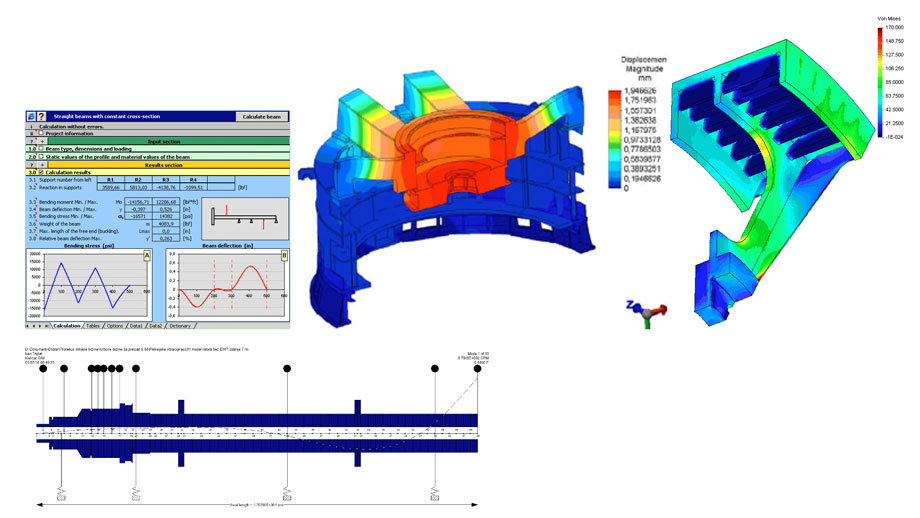

Design and engineering

Using state-of-the-art techniques allows us to calculate the various components and the complete generator. We have a suite of computational tools at our disposal, including proprietary software for electromagnetic calculations, ventilation, and heat analysis, alongside industry-standard tools such as Autodesk Simulation, AutoCAD, Rotlat, Mitcalc, OpenFOAM, Magnet, SolidWorks Simulation, Neplan 360, and others.

Quality control

Control monitors the entire manufacturing process, starting from the intake of raw materials and components at the factory (Input and Mechanical Inspection) through manufacturing (Input and Mechanical Inspection, including Interim Electrical Control) and final delivery and commissioning at the power plant (Final Electrical Control Department). Through collaborative efforts with other departments, we achieve superior control over the manufacturing process, components and the generator, all designed to ensure long-term reliable operation within hydropower plants.

Manufacturing

Leveraging the advantages of in-house manufacturing, we offer efficient adaptations that are often synonymous with our products and services. Our notable manufacturing activities include the manufacturing of stator laminations (punching or laser cutting), lamination, rotor and stator windings, locksmith services, mechanical machining, and assembly works. At our manufacturing facility, highly skilled and experienced employees operate a diverse range of machines, including:

- GURUTZPE GL 10.5.3 and GURUTZPE GLH 25.40.10 Horizontal Lathes

- TOS FUT 300/125 Horizontal Machining Centre

- Hydraulic press HENRY-BERRY

- SCHENCK CAB 820 Measuring Units for Universal Balancing Tasks

- SCHULER NN20 and SCHULER N20S Notching Press

- SCHULER Metal Dying Machine

- RIMAC Flat Wire Cut-to-Length and Stripping Machine

- VINCENT Coil Forming Machine

- MICAMATION Pole Coil Brazing Machine

- ANT-300 CNC and ANT-400 CNC Coil Winding Machine

- VTI IMPRMB VPI2R Vacuum Pressure Impregnation (VPI) System for Windings with Nanoparticles

- GVPI System for Low-Voltage Coil Vacuum Pressure Impregnation

- Vacuum Pressure Impregnation System for Stator Winding Bars

- Vacuum Pressure Impregnation System for Poles

- Rimac PRC-P 1226 Pole Press

Site activities

With prompt, expert, and top-quality on-site execution, we provide support throughout the full lifecycle of our products.

We harness all our resources, in particular the Technical Office, Manufacturing, Quality Control, Occupational Health and Safety, and Project Management Office, to organize and carry out off-premise tasks. Additionally, we partner up with local subcontractors and service providers when executing contracted projects at sites worldwide.